Ceres Technology’s Predictive Analytics Engine Forecasts Generic Drug Delays For A Top 5 Pharma Company

Nostradamus AI predicts supply chain disruptions months in advance, with up to 80% accuracy, changing how companies manage risk

February 15th, 2023 – The pharmaceutical industry is a complex and ever-evolving landscape, with a constant need for reliable and accurate predictions to optimize supply chain management and minimize the number of canceled orders. This is where Ceres Technology comes in, providing cutting-edge predictive analytics for the pharmaceutical industry and revolutionizing how companies approach their supply chain management.

Ceres Technology was recently successful in predicting generic drug delays for a major pharma company up to six months in advance using its patent pending Nostradamus™ AI platform.

The pharma company achieved an ROI of 10x in the first year alone by reducing the number of canceled orders due to shipment delays, allowing for more efficient and effective supply chain management.

Nostradamus’s predictive power is not just based on traditional logistics data, but it is augmented with several external factors, including macro and micro economic data, financial data, and geopolitical data, with more than 17,000 data sets from various sources. The solution uses advanced AI systems to analyze linear and non-linear data to find trends and patterns, enabling users to predict whether or not a generic drug will be delayed.

Bobby Katoli, CEO of Ceres Technology, said, “Nostradamus uncovered that rainfall in India was one of the leading contributors to shipment delays in the manufacturing of generic drugs. As many in the industry know, Hyderabad manufactures many of the world’s generic drugs. Unfortunately, Hyderabad’s electrical system is not well-equipped to handle excessive rain,” Katoli added. “As a result, there have been a few instances, in just the past two years, where excessive rain caused power outages to Hyderabad’s homes and factories. In short, the more rainfall in Hyderabad, the more of a chance the electrical grid will shut down, which halts manufacturing.”

Another interesting factor found by Nostradamus was the impact of Nigeria’s cash reserves on the delivery of generic drugs. India is one of Nigeria’s largest trading partners, which includes numerous generic drugs. Additionally, India has invested in and built generic drug manufacturing sites in Nigeria that are hubs for manufacturing and distribution to other parts of Africa. Falling cash reserves in Nigeria can potentially lead to a decrease in the value of the Nigerian currency, making generic drugs imported from India more expensive. More expensive Indian drugs can decrease Nigerian demand, which shrinks the volume of exports from India to Nigeria. The converse of this is also true; higher reserves can lead to higher currency appreciation, making generic drugs from India less expensive and increasing Nigerian demand. Additionally, Nigerian cash reserves and currency appreciation/depreciation can have secondary effects across the African continent for Nigerian-produced and Indian-funded drug manufacturing.

These insights demonstrate the power of Nostradamus’s predictive supply chain analytics and its ability to provide valuable information beyond traditional logistics data. By incorporating external factors, companies can have a more comprehensive and accurate picture of future delays, allowing for more effective supply chain resilience.

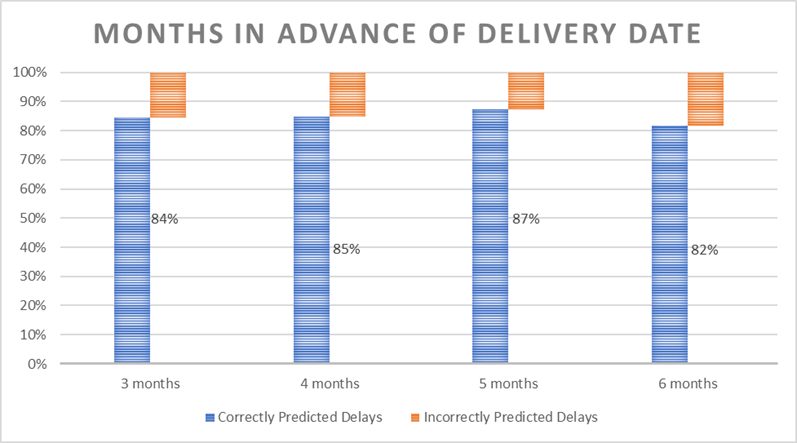

The below graph shows the performance and accuracy of our predictions for different time intervals of 3, 4, 5, and 6 months before the expected delivery date. The graph clearly shows the accuracy of our predictions and the benefits that can be achieved through the use of Nostradamus’s predictive analytics.

The accuracy of prediction is key (the higher the accuracy of the prediction, the higher the value of such a prediction for our clients). The figure above shows the percentage of correctly predicted delays versus incorrectly predicted (true positives vs false negatives) delays for various generic drugs.

Nostradamus enabled this pharma company to attain a minimum of 82% accuracy at time thresholds of 3, 4, 5, and 6 months before the expected delivery date.

Before using Nostradamus, the pharma company could only achieve predictability up to 3 weeks in advance, which means Ceres increased the predictability time horizon by 8x.

In conclusion, Ceres Technology’s predictive analytics revolutionizes how the pharmaceutical industry approaches supply chain management by providing a valuable tool for companies to optimize their supply chains, minimize the number of canceled orders, and maximize revenue opportunities. By providing early warning signs of potential upstream manufacturing and shipment delays, companies can make proactive decisions to reduce the impact of those delays.

In addition to reducing the number of canceled orders, Nostradamus allowed the company to identify which suppliers were most at risk. This information enabled them to place their purchase orders with suppliers with lower risk profiles and stock up on inventory now in anticipation of future delays. This ability to see the future risk of shipment delays by the supplier not only improves supply chain efficiency but also helps to ensure that the company’s customers receive the drugs they need when they need them.

“We believe this is a game-changer for the pharmaceutical industry, providing valuable insights and enabling companies to make more informed decisions about their supply chain management,” Katoli added.

ABOUT CERES TECHNOLOGY

Ceres Technology is a leader in AI-driven supply chain management solutions development that enables companies to reduce risk and increase resiliency by finding patterns and trends in data to predict upstream disruptions, often months in advance. Their lead solution, Nostradamus, aggregates data from almost any source and provides actionable analysis and granularity at the individual item. Applying the latest AI and machine learning technology allows customers to have full multi-modal visibility from purchase to delivery and glean insights to mitigate the risk of disruptions.

Media Contact

Company Name: Ceres Technology

Contact Person: Kevin Kohleriter

Country: United States

Website: https://www.cerestech.co/